- Anisotropic Crystalline Etch Simulation Model

- Anisotropic Crystalline Etch Simulation Tools

- Anisotropic Crystalline Etch Simulation Method

Simulation of Anisotropic Chemical Etching of Single Crystalline Silicon using Cellular-Automata

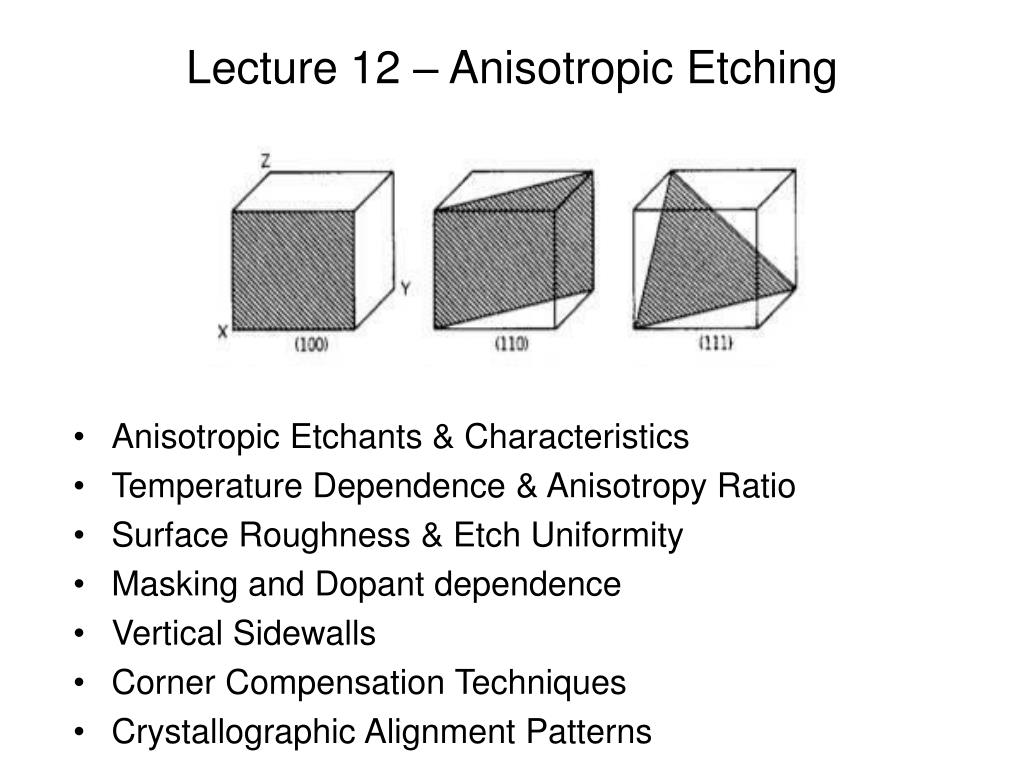

Anisotropic crystalline etching simulation (ACES) program based on a new continuous Cellular Automata (CA) model. The program provides accurate modeling of etching process with high spatial resolution. Implementation of a dynamic CA technique has resulted in increased simulation speed and reduced memory requirements. A first ACES software based. An atomistic model for the simulation of anisotropic wet chemical etching of crystalline silicon is developed. Special attention is paid to the relation between the atomistic processes, the mesoscopic features of the surface morphology and the macroscopic anisotropy of the process, bridging the different length scales. Abstract Anisotropic chemical etching of crystalline silicon in aqueous KOH is simulated at the atomic level using a cellular automata model. Experimental etch-rate ratios as well as the influence of temperature and concentration of the etchant are taken into account by introducing a stochastic component. With the help of two examples, the underetching of a convex mask corner and mask-corner. Sensors and Actuators A, 31(1992) 267 274 267 Anisotropic crystal etching: a simulation program J. Delapierre LET1/DOPTfSCMM-CEA -CENG 85X, 38041 Grenoble C dex (France) Abstract In the field of micro-devices, tools are actually needed to model the fabrication processes, especially the shapes resulting from chemical etching of a monocrystal.

Abstract

We propose a new concept for anisotropic single crystalline silicon (Si) etching simulation. Our approach combines three calculation modules, a molecular dynamics calculation module to define chemical reaction probability, a Cellular-Automaton module to calculate etching rate, and a Wulff-Jaccodine graphical method module to predict an etched shape. This configuration allows mm scale process simulation based on atomic scale physical chemistry of anisotropic Si etching. In this paper, the performance of a newly developed Cellular-Automata module, called CAES (Cellular-Automata Etching simulator), is presented as a first step towards the realization of our simulation concept.

Anisotropic Crystalline Etch Simulation Model

Anisotropic Crystalline Etch Simulation Tools

- simulation;

- anisotropic;

- wet etching;

- silicon;

- molecular dynamics;

- Wulff-Jaccodine;

- Cellular-Automata